Ring Cutting Procedures for Very Hard Metals using the GEM II Ring Cutter

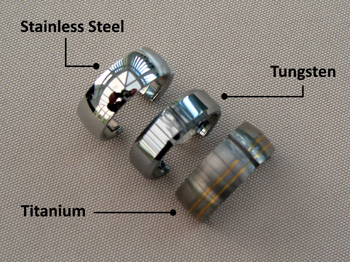

Cutting tests carried out using the GEM II battery powered ring cutter on jewellery rings made from Tungsten, Titanium and Stainless Steel.

Source of test rings made from Tungsten, Titanium and Stainless Steel: ARGOS

Non-jewellery ring: Brass - Toolstation

Ring Materials Tested

| RING MATERIAL | WIDTH (mm) | THICKNESS (mm) | WEIGHT (gms) |

|---|---|---|---|

| Tungsten (Argos Ref: 240/8057) | 7.0 | 2.30 | 12.0 |

| Titanium (Argos Ref: 240/8909) | 9.5 | 2.60 | 4.40 |

| Stainless Steel (Argos Ref: 240/7663) | 8.0 | 2.50 | 7.0 |

| Brass (Plumbers Olive) | 6.4 | 1.0 | N/A |

Ring Material Features

| RING MATERIAL | DESCRIPTION | HARDNESS (MOHS Scale) |

|---|---|---|

| Tungsten | Highly polished, mirror like finish. Colour similar to cobalt steel ballrace. Densest and heaviest of the metals tested as well as being extremely hard. | 7.5 to 8 |

| Titanium | Predominantly supplied in a matt grey finish, very light weight and could be mistaken for aluminium but unlike aluminium it is very hard. | 6 to 6.5 |

| Stainless Steel | Highly polished and silver in colour. Quite hard. | 5.5 to 6.3 |

| Brass | Gold/Copper like in colour. Relatively soft. | 1.0 |

Power Source Deployed:

4 x AA Size 2500 Mah fully charged NiMh rechargeable batteries.

Procedure:

For all metals featured in the tests, excluding Brass, the diamond disc was selected. Owing to the high tensile strength of

the rings, 2 cuts are required to be made with the diamond disc at opposing sides of the ring. The first cut to a depth of

approximately 75% of the thickness of the ring. This first cut is to reduce the tension in the ring. The second cut, at a

location approximately 180 degrees to the first cut, is to go all the way through the ring. The blade of the screwdriver,

provided in the GEM II kit, will be inserted into the cut and twisted to open the ring.

To reduce the heat in the ring and frictional wear on the cutting edge of the disc, liquid detergent (Fairy Liquid) was repeatedly squirted on to the cutting site. Liquid detergent closely resembles an oil and water mix deployed in engineering during milling and turning to cool and reduce frictional wear on drill bits.

Tungsten Ring Cutting Prodcedure - 3 x Diamond Discs

| Cutting Location No. | Cutting Time (min) | Cooling Time (min) |

|---|---|---|

| 1 | 3 | - |

| Disc Replaced | - | - |

| 2 | 3 | - |

| Disc Replaced | - | - |

| 2 | 1 (ring cut through) | - |

| 1 | 2 (ring cut through) | - |

| TOTAL: 9 Min | TOTAL: 0 Min | |

| No. of discs used: 3 | Overall Time Taken: 9 Minutes | |

Three diamond discs were deployed; all three had virtually no diamond grit remaining on disc's cutting edge.

Due to the very high tensile strength in the Tungsten ring, the tension relieving cut of 75% of the thickness of the ring did not weaken the tension sufficiently to allow the prizing apart of the ring. It was decided to cut all the way through the ring in both locations.

The integrity of the cutting edge of the disc was established at the outset and periodically during the cutting process.

Owing to the fact that the cutting edges of all three diamond discs were virtually completely smooth after the above test a two disc cutting test was abandoned.

Titanium Ring Cutting Prodcedure - 3 x Diamond Discs

| Cutting Location No. | Cutting Time (min) | Cooling Time (min) |

|---|---|---|

| 1 | 3 | - |

| Disc Replaced | - | - |

| 2 | 3 | - |

| Disc Replaced | - | - |

| 2 | 4 (ring cut through) | - |

| Attached 2nd used cutting disc as this had more grit on the cutting edge. | - | 5 |

| 1 | 3.5 | - |

| TOTAL: 13.5 Min | TOTAL: 5 Min | |

| No. of discs used: 3 | Overall Time Taken: 18.5 Minutes | |

* A fine layer of grit was left on the cutting edge of all three discs, suggesating very limited re-use.

Titanium Ring Cutting Prodcedure - 2 x Diamond Discs

| Cutting Location No. | Cutting Time (min) | Cooling Time (min) |

|---|---|---|

| 1 | 5 | - |

| Disc Replaced | - | - |

| 2 | 5 | - |

| - | - | 15 |

| Reused cutting disc with the most residual grit left on the cutting edge | - | - |

| 1 | 1.5 (ring cut through) | - |

| 2 | 2 | - |

| TOTAL: 13.5 Min | TOTAL: 15 Min | |

| No. of discs used: 2 | Overall Time Taken: 28.5 Minutes | |

* The cutting edges of the discs were too worn for re-use.

The actual cutting times between three disc and two disc usage were identical. However due to wear on the cutting edge of both discs and the extra effort on behalf of the motor during the first 10 minutes a 15 minute cooling off period was required to prevent damage to the motor. Consequently the overall time of the procedure increased by 10 minutes.

In the above tests the tension relieving cutting depth had to be increased from the normal 50% - 75% of the thickness of the ring to 90% due to the high tensile strength of the titanium. This would allow for prizing the ring apart using a screwdriver blade.

Stainless Steel Ring Cutting Prodcedure - 2 x Diamond Discs

| Cutting Location No. | Cutting Time (min) | Cooling Time (min) |

|---|---|---|

| 1 | 3 | - |

| 2 | 3 | - |

| Disc replaced | - | - |

| 2 | 1 (ring cut through) | - |

| TOTAL: 7 Min | TOTAL: 0 Min | |

| No. of discs used: 2 | Overall Time Taken: 7 Minutes | |

Two discs were deployed, the 2nd disc was in use for just 1 minute and as a consequence the disc had ample grit left on the cutting edge allowing for future usage.

Stainless Steel Ring Cutting Prodcedure - 2 x Diamond Discs

| Cutting Location No. | Cutting Time (min) | Cooling Time (min) |

|---|---|---|

| 1 | 3 | - |

| 2 | 5 (ring cut through) | - |

| TOTAL: 8 Min | TOTAL: 0 Min | |

| No. of discs used: 2 | Overall Time Taken: 9 Minutes | |

* A very fine layer of grit remained on the cutting edge of the disc but it was insufficient to guarantee effective re-use.

In both tests the tension relieving cut was to a depth of approx. 75% of the thickness of the ring.

Brass Ring Cutting Prodcedure - Single Carbide Disc

| Cutting Location No. | Cutting Time (min) | Cooling Time (min) |

|---|---|---|

| 1 | 35 seconds | - |

| TOTAL: 35 Seconds | TOTAL: N/A | |

| No. of discs used: 1 | Overall Time Taken: 35 Seconds | |

Summary

During the cutting process 15% more Stainless Steel and 45% more Titanium was removed compared to Tungsten. Below are the adjusted times for the differences in ring width and thickness.

| TUNGSTEN | TITANIUM | STAINLESS STEEL |

|---|---|---|

| 9.00 Min | 9.31 Min | 6.00 Min |

It was possible to reduce the number of discs used to cut through rings from the number deployed in the original tests except for the ring made of Tungsten.

Titanium: The actual cutting time while using two disc or three discs was identical. However the procedure time for using 2 discs increased by 10 min due to the requirement for an extended cooling off time to preserve the motor.

Stainless Steel: Cutting time with 1 discs took longer than cutting with 2 discs by 2 minutes, though no extended cooling off period was required.

IMPORTANT:

- The application of a lubricant in a frequent and liberal manner is essential to the cutting performance of the disc and the GEM II Ring Cutter's motor. This improves the speed and efficiency of the cutting procedure as it reduces frictional resistance. It also reduces the heat generated in the ring, which will in turn prolong the serviceability of a cutting disc.

- Verification of the serviceability of the cutting edge of the diamond disc is also essential to its performance. To verify, run your finger around the outer perimeter of the disc and if over 80% of the surface feels smooth, replace the disc before proceeding with the cutting process.

- Operators must be very conscious in the number of minutes of continuous cutting they have performed. Great care

must be taken not to allow the GEM II's motor to overheat. Cutting performance diminishes as the temperature within the

motor increases and if left unchecked will lead to permanent motor damage. In general the following procedures should be

followed;

- Continuous cutting for 10 min, allow a cool off period for 15 min.

- Continuous cutting for 7-8 min, allow a cool off period for 10 min.

- In these tests liquid detergent was used as a lubricant because of its oil-like consistency but any water based gel, such as KY Jelly, moisturising hand lotion or anti-bacterial hand wash gel should produce the same results.

- Our tests were carried out using 2500 MaH NiMh rechargeable batteries. The four rings were cut through using a single set of fully charged batteries. Although tests were not carried out using alkaline batteries, we estimate that for Tungsten and Titanium rings, two sets of fresh batteries would be required.